Mobile container for removing micropollutants: Gdańsk – Szczecin – Kaunas – Riga

18 December 2024

Mobile container for removing micropollutants at the advanced effluent treatment stage. This pilot enables testing most efficient sequences of technologies for removing micropollutants, as well as testing PFAS removal efficiency. After the series of pilots in several countries, the experiences and findings are presented in the EMPEREST output “Strategies and technological means for minimising organic micropollutant emissions from WWTPs” (PDF). This document will support wastewater treatment plants in making informed decisions about cost-effective technologies for micropollutant removal to unlock future large-scale investments imposed by the regulation changes.

Map

Pilot plant constructed by: Gdansk Water Utilities (GIWK)

Partners participating in the piloting: Gdansk Water Utilities, Water and Sewage Company Ltd. of Szczecin, “Kaunas water” Ltd., “Riga Water” Ltd., University of Tartu, Berlin University of Technology, Turku University of Applied Sciences.

Why to test?

The revised Urban Wastewater Treatment Directive came into force on 5 November 2024, putting on track the ambition for the zero-pollution Europe, particularly in respect to micropollutants. According to the revised directive, Member states will have to ensure the application of the treatment steps meeting new thresholds for quaternary treatment in larger plants of 150 000 PE and above by 2045. The ambition of EMPEREST is to smoothen the process of preparing for such large infrastructural investments and allow WWTPs to discover the most suitable sequence of effective quaternary treatment technologies through the series of tests by means of the mobile pilot containers.

Technologies

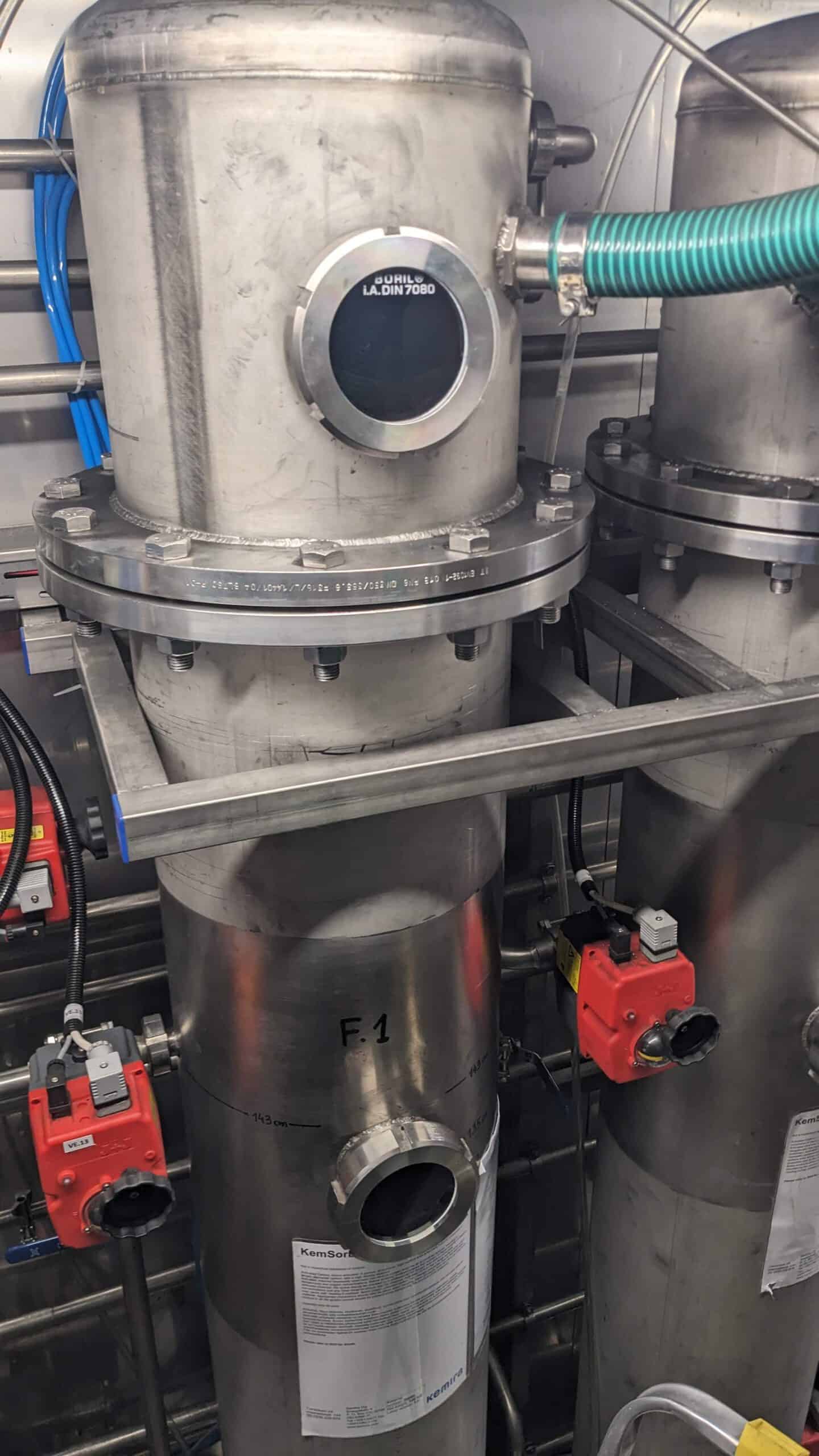

The pilot test aims at identifying the optimal technological process parameters and evaluating the wastewater treatment efficiency. The tested treatment train consists of cloth filtration, ozone oxidation, granular activated carbon adsorption and ion exchange. The system’s performance was monitored remotely using UV absorbance and turbidity online sensors. The efficiency of the treatment process was evaluated based on laboratory analyses of grab and 24-h composite samples, collected on a regular basis twice a week.

Progress at piloting locations

GDAŃSK | May – July 2024

The pilot test was conducted at the Wschód WWTP in Gdańsk from 7 May 2024 to 11 July 2024. After the start-up of the plant and quick resolving of some technical issues, the piloting began.

The examined micropollutants included 20 PFAS substances (PFASs), 11 pharmaceuticals, 3 herbicides, 2 estrogens, 2 phenols, and sum of 2 benzotriazoles. The highest treatment efficiency was observed with an ozone dose of 10 g/m3, ozonation contact time of 30 min, an adsorption contact time of 20 min, and ion exchange contact time of 30 min. Except for PFAS, the removal rate of all micropollutants in the oxidation and adsorption processes was very high, ranging from 87 to 100%, depending on the type of compound. Ion exchange treatment removed 100% of the PFAS and other micropollutants present in the effluent of the adsorption process. As expected, a decrease in total nitrogen and total phosphorus levels in the effluent of the tested treatment train was also noted, ranging from 68-79% and 32-58%, respectively.

A significant advantage during the pilot study was the ability to remotely monitor process efficiency and control the pilot plant. The pilot plant was equipped with an advanced control system and on-line UV absorbance and turbidity sensors, enabling remote process monitoring and operation of individual devices. The tested combination of advanced treatment technologies has demonstrated a high efficiency in removing organic micropollutants.

- Report (PDF): Pilot-scale removal of micropollutants at the Wschód WWTP in Gdańsk (Annex 1 of the output 2.3)

Photos of the mobile pilot container and the technologies within, by Gdansk Water Utilities.

Following the testing at the Wschód WWTP, the pilot plant was transported and successfully commissioned at the Pomorzany WWTP in Szczecin for testing the removal of micropollutant from wastewater discharged to the environment. This demonstrates that the mobile, plug-and-play pilot plant is a highly cost-effective tool to support upgrading and development of numerous wastewater treatment plants.

Transporting the pilot plant from Gdansk… (photo by Gdansk Water Utilities)

… to Szczecin. (Photo by Water and Sewage Company Ltd. of Szczecin)

SZCZECIN | September 2024 – January 2025

The pilot research station was transported to Szczecin on 22 August 2024. At the beginning of September, the station was connected and prepared for operation. An external company was called in to check and calibrate the measurement probes. After the full launch in the third week of September, the station operated continuously from Monday to Friday.

Current indications of probes and flows were written down and analyzed, and a schedule of analyses was developed. The first average daily samples were taken at the end of September, at four points: the inlet to the treatment plant, wastewater after biological treatment, wastewater after filtration on a fabric filter, wastewater after filtration on activated carbon. In addition, a momentary sample was taken from the tank after ozonation several times. The operation of two types of activated carbon was tested. A total of 11 repetitions were performed.

- Report (PDF): Pilot-scale removal of micropollutants at the WWTP Pomorzany in Szczecin (Annex 2 of the output 2.3)

KAUNAS | January – May 2025

The mobile piloting container, transferred from Szczecin, arrived at the Kaunas wastewater treatment plant on 9 January 2025. During the following week, the container was connected to the biologically treated wastewater and prepared for operation. Additional preparations were required due to winter conditions during the planned piloting period.

EMPEREST mobile container connected at the Kaunas wastewater treatment plant during winter. Photo by “Kaunas Water” Ltd.

The first average daily samples were taken at the end of January at four locations: the inlet to the wastewater treatment plant, wastewater after cloth filtration, wastewater after the ozone contact tank, and wastewater after granular activated carbon (GAC) filtration. Two types of different activated carbon media were tested. The examined organic micropollutants included 49 PFAS substances, 12 pharmaceuticals, 10 phthalates, and the sum of 2 benzotriazoles.

A total of 10 testing series were conducted under varying operational parameters, such as different ozone doses, contact times in the ozone reactor, and contact times in the GAC filters. The piloting period lasted until early May, with testing performed only during dry weather flow conditions.

Photos from the piloting by “Kaunas Water” Ltd.

The mobile piloting container proved easy to operate and maintain, thanks to its sophisticated automation system, online sensors, and remote monitoring capabilities.

At the conclusion of the piloting activities, an external company carried out a full service of the pilot plant equipment and prepared it for transport to the next location – Riga, taking over the testing of technologies as an immediate transfer activity spanning even beyond the project.

Interactive map showing pilot locations. Use the arrow keys to move the map view and the zoom controls to zoom in or out. Press the Tab key to navigate between markers. Press Enter or click a marker to view pilot project details.