Mobile container for removing micropollutants: Tartu – Tallinn – Turku

29 January 2025

Mobile container for removing micropollutants at the advanced effluent treatment stage. This pilot enables testing most efficient sequences of technologies for removing micropollutants, as well as testing PFAS removal efficiency. After the series of pilots in several countries, the experiences and findings are presented in the EMPEREST output “Strategies and technological means for minimising organic micropollutant emissions from WWTPs” (PDF). This document will support wastewater treatment plants in making informed decisions about cost-effective technologies for micropollutant removal to unlock future large-scale investments imposed by the regulation changes.

Map

Pilot plant constructed by: Tartu Waterworks Ltd. and University of Tartu

Partners participating in the piloting: Tartu Waterworks Ltd., Tallinn Water Ltd., Turku Region Wastewater Treatment Plant, University of Tartu, Berlin University of Technology, Turku University of Applied Sciences.

Why to test?

The revised Urban Wastewater Treatment Directive came into force on 5 November 2024, putting on track the ambition for the zero-pollution Europe, particularly in respect to micropollutants. According to the revised directive, Member states will have to ensure the application of the treatment steps meeting new thresholds for quaternary treatment in larger plants of 150 000 PE and above by 2045. The ambition of EMPEREST is to smoothen the process of preparing for such large infrastructural investments and allow WWTPs to discover the most suitable sequence of effective quaternary treatment technologies through the series of tests by means of the mobile pilot containers.

Technologies

Tartu has designed the pilot plant to operate either in a single in-line configuration or in two separate parallel lines. This flexible setup aims to identify the most effective combinations of technologies for achieving higher micropollutant removal rates. The plant incorporates several key treatment steps: a pile cloth media filter for removing total suspended solids (TSS), ozonation to break down larger molecules, a sand filter for eliminating particles and suspended solids, two granular activated carbon (GAC) filters for micropollutant removal, and UV disinfection for treating the effluent. Additionally, nanofiltration operates independently from the main pilot plant and also targets micropollutant removal. Toward the end of January and early February 2025, powdered activated carbon (sPAC) will be tested in combination with the pile cloth media filter.

Progress at piloting locations

TARTU | April – August 2024

Tartu Waterworks conducted sampling throughout its operations, with data collected via an automatic analyzer from the beginning of its operations until the end of August 2024. Effluent water from the wastewater treatment plant, which also served as the inlet for pilot testing units, was analyzed for micropollutants before the pilot testing commenced. This preliminary testing helped us understand the composition of our effluent and identify which parameters needed to be measured, as well as those that were unnecessary due to their absence in our waters.

Samples for PFAS, pharmaceuticals, and other micropollutants were collected once or twice a month and sent to various laboratories for analysis. Samples were consistently taken from the inlet to establish a baseline for pollutant concentrations, as well as after different treatment stages, such as ozonation, granular activated carbon (GAC) filtration, UV treatment, and others.

As anticipated, granular activated carbon and ozone proved most effective at reducing pharmaceuticals, PFAS, and other micropollutants. Surprisingly, nanofiltration showed remarkable efficacy against PFAS compounds but simultaneously concentrated pharmaceuticals and other micropollutants with smaller molecular size and higher initial concentrations.

Our findings revealed that one single technology cannot effectively treat all micropollutants in the effluent. Instead, a combination of sequential treatment technologies, each with specific strengths, is required. By employing this multi-stage approach, pollutant concentrations were significantly reduced after the fourth treatment stage.

Photos of the mobile pilot container and the technologies within, by Ornella Mundi, Tartu Waterworks Ltd.

After the testing period at the Tartu WWTP, the pilot plant was transported to the Tallinn WWTP for further local testing.

Transporting the pilot plant, photo by Ornella Mundi, Tartu Waterworks Ltd.

TALLINN | August 2024 – February 2025

Tallinn Water Ltd. collected samples at four different time and analysed them for PFAS compounds and pharmaceuticals. The samples were taken from the biofilter (pilot influent), drum filter, ozonation stage, and two granular activated carbon (GAC) filters, GAC A and GAC B. Additionally, the TFA was analysed, which is now recognized as a challenge for the plant.

The results showed that granular activated carbon was the most effective treatment for PFAS removal without ozonation, as some PFAS concentrations increased after ozonation. However, for pharmaceuticals, ozonation proved to be the more effective treatment method.

- Report (PDF): Pilot-scale removal of micropollutants at the Tallinn WWTP (Annex 5 of the output 2.3)

Setting the pilot plant in Tallinn, photo by Jelena Valtin, Tallinn Water Ltd.

TURKU | March – June 2025

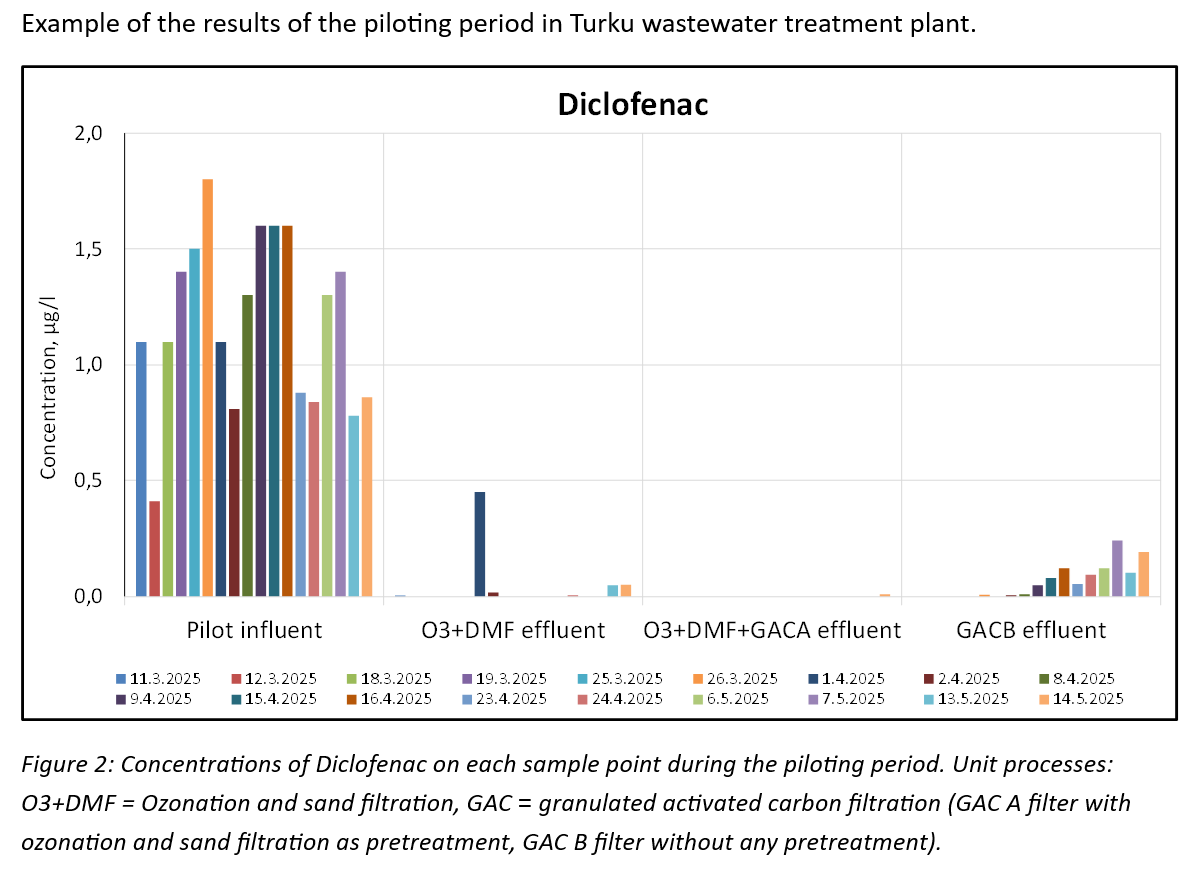

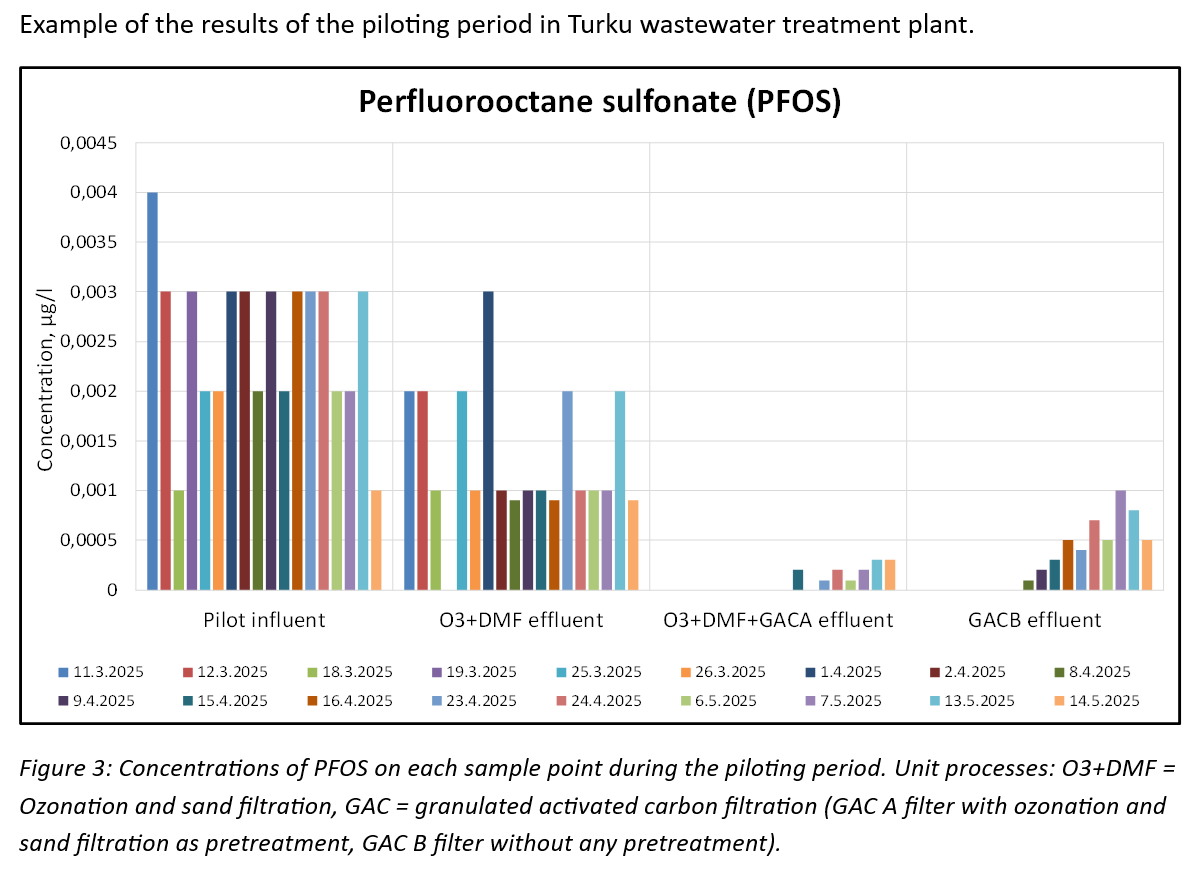

Turku Region Wastewater Treatment Plant conducted a 13-week pilot study from beginning of March until the end of June 2025. Secondary clarified effluent was directed into the pilot plant and divided into two parallel treatment lines: the first line included ozonation combined with sand filtration, followed by granular activated carbon filtration, followed by UV treatment. The second line included granular activated carbon followed by UV treatment. Samples were collected twice a week throughout the piloting period from the pilot influent, ozonation + sand filtration effluent, and effluents of both granulated activated carbon filters.

The results show that granular activated carbon is highly effective in removing pharmaceuticals and PFAS compounds with sufficient contact time. However, the activated carbon becomes saturated quickly and requires pre-filtration to maintain its adsorption capacity. Ozonation alone is insufficient and can increase some PFAS concentrations, but the combination of ozonation and sandfilter prior activated carbon filtration is effective and protects the adsorption capacity of activated carbon.

Arrival of the pilot plant, photo by Mia Aitoukazzamane

Interactive map showing pilot locations. Use the arrow keys to move the map view and the zoom controls to zoom in or out. Press the Tab key to navigate between markers. Press Enter or click a marker to view pilot project details.