Greening Port Operations - OPS for pelagic vessels

03 July 2024

Meeting the demands of Pelagic vessels

Emission reduction from vessels in port is crucial for lowering greenhouse gas emissions and improving environmental outcomes and public health in coastal towns and communities. Ports are implementing various strategies to reduce the environmental footprint of maritime operations, focusing on emissions from vessels during their port stays.

Pelagic fishing vessels present a particular challenge for decarbonization. Their unloading operations often run for 10 to 30 hours, requiring continuous energy for pumping, cooling, and hydraulic systems. Traditionally, this energy has been supplied by auxiliary diesel engines, leading to significant emissions and costs.

Cutting emissions, Powering the future

Onshore power supply (OPS) to ships at berth is a well-established technology for certain ship types which helps reduce emissions in ports. It allows ships to shut down their engines and generators and use electricity generated onshore, which have significantly lower air pollutant emissions and, depending on the grid GHG emission factor, often also lower emissions of greenhouse gases. However, the deployment of OPS requires a well-planned infrastructure capable of delivering sufficient electrical power to meet the demands of various vessels. This involves developing grid connections, substations, and, when necessary, frequency converters, along with installing shore connection panels.

Green power at the quay: OPS comes to Skagen

The Port of Skagen has taken a decisive step toward climate-neutral operations with the commissioning of its first Onshore Power Supply (OPS) system. Instead of relying on diesel generators during unloading, vessels can now plug directly into certified renewable electricity. This shift reduces CO₂ emissions, cuts harmful air pollutants, and creates a quieter working environment on the quayside.

The OPS system in Skagen was designed to meet these heavy power demands while ensuring international compliance, safety, and flexibility. Its capacity reaches 1.5 megawatts, enough to cover even the most energy-intensive landing operations. Two connection points have been installed at the port’s main landing sites—FF Skagen, which handles fishmeal production, and Scandic Pelagic, which processes fish for human consumption. A semi-automated cable management system extends 45 meters, ensuring vessels of different sizes and quay positions can connect efficiently.

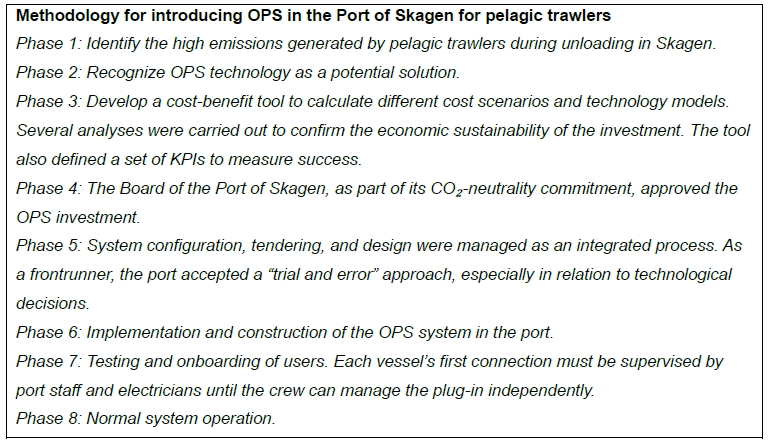

Methodology of implementing OPS at the Port of Skagen in the IBSR BSC Project

The facility is designed to provide an OPS power output of 850kW through three 350A cable connections. It will be capable of accommodating a range of voltage levels (from 400V to 690V) and frequencies (either 50Hz or 60Hz). The infrastructure is housed in a 10-foot container for enhanced flexibility. The system was successfully tested in May 2025 with the vessel HM379 Lingbank, marking a milestone in demonstrating that high-capacity shore power can meet the operational needs of the pelagic fleet. The operation of the OPS system was structured for reliability, safety, and simplicity, with clearly defined roles between port personnel and vessel crew. The process is as follows:

- Advance notification

- CMS transport and setup

- Cable handling and shore connection

- Vessel connection

- Power supply during unloading

- Post-use handling and billing

Insights for other Ports to replicate Skagen’s success

The implementation in Skagen has highlighted several important lessons for other ports. One is the value of building the infrastructure first, even before vessels are fully OPS-ready. This approach breaks the common “chicken-and-egg” dilemma and demonstrates leadership that can encourage vessel owners to invest in retrofits.

Another lesson is the importance of flexibility. The OPS system was designed to support multiple voltages and frequencies and is equipped with a mobile cable management system to accommodate vessels of different types and sizes. This adaptability has proven crucial for real-world operations.

Collaboration has also been a key success factor. Shipowners, processors, port staff, and grid operators were involved from the very beginning, ensuring that the OPS design matched actual workflows and operational needs. Finally, fixed and transparent electricity pricing has been essential in creating trust among users and encouraging early adoption.

The experience in Skagen now serves as a roadmap for other fishing ports considering OPS investments. It shows the value of setting clear climate targets, engaging stakeholders early, measuring real energy demand, and ensuring compliance with international standards. It also underlines the importance of planning for vessel retrofits alongside infrastructure development, testing systems under real operating conditions, and gathering user feedback early in the process.

From local pilot to regional blueprint

The OPS solution for electrifying the pumping and cooling activities of pelagic landings is an integral part of the Interreg Baltic Sea Region Blue Supply Chains initiative. Simultaneously, the cable management aspect of shore power is included in the Interreg North Sea Region project Green Supply Chains. These collaborative projects highlight the port’s commitment to sustainable practices and innovative solutions within the broader regional context. Supported by Interreg, this case provides a blueprint for how ports can lead the way in maritime decarbonization.

Interactive map showing pilot locations. Use the arrow keys to move the map view and the zoom controls to zoom in or out. Press the Tab key to navigate between markers. Press Enter or click a marker to view pilot project details.