Pilot 1 - Treatment of RAS water for use as technical water

26 April 2023

Pilot Owner: Business Lolland-Falster

Location: Lolland-Falster, Denmark

Partners involved: Blue Research (DK), Klaipeda Science and Technology Park (LT), and Klaipeda University (LT)

Type of symbiosis: water

Keywords: RAS, saltwater, technical water, water treatment technology, process water

Background

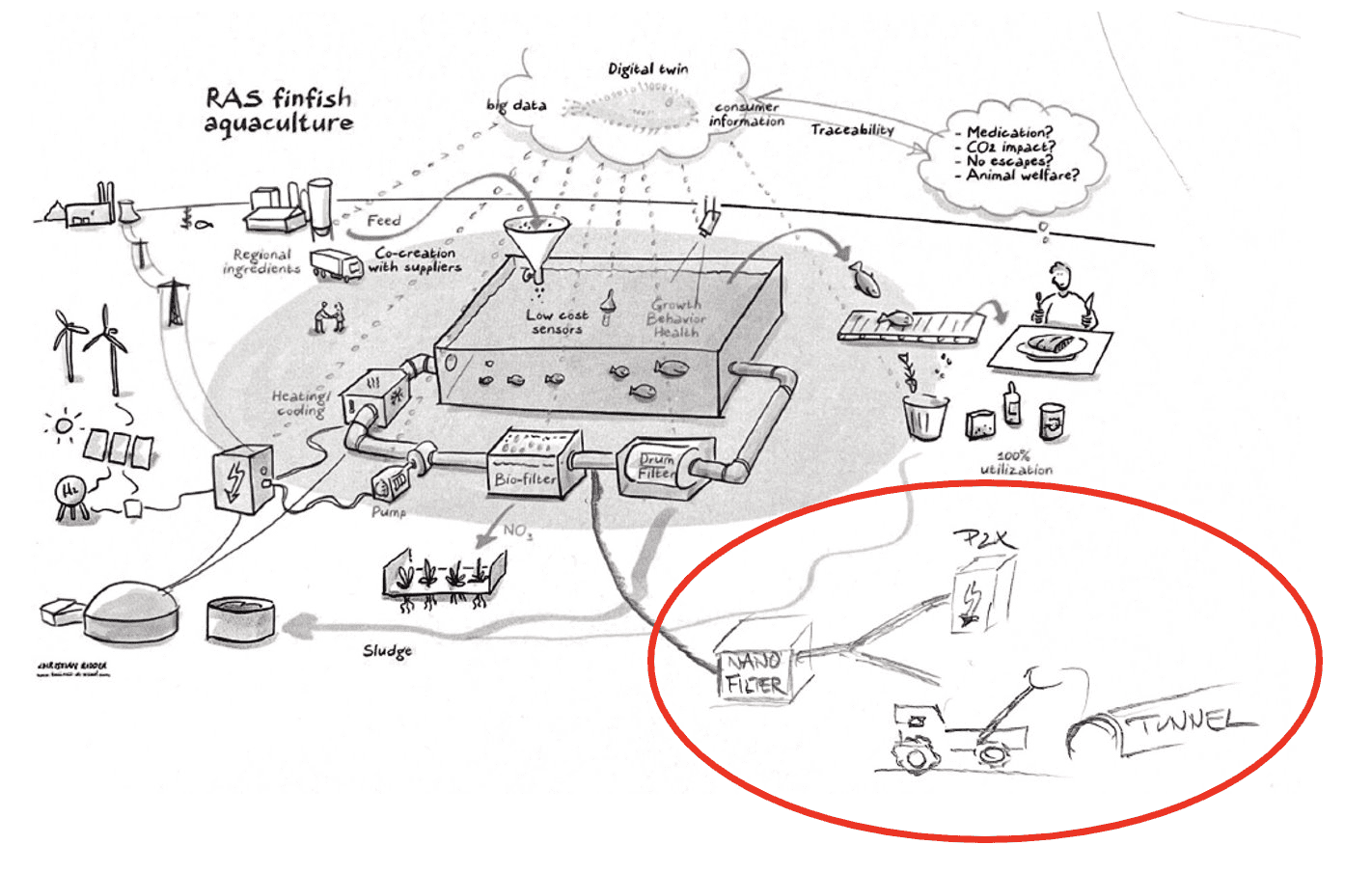

In RAS, water is continuously reused and recycled through the system, which helps to optimize water use and reduce the environmental impact of aquaculture operations. For this, advanced water treatment technologies such as biofiltration, ozonation, and UV sterilization can be used to maintain water quality. However, water quality deteriorates over time due to the accumulation of metabolic waste products, uneaten feed, and other compounds. Therefore, a low percentage of the water volume needs to be renewed periodically to replace water losses due to evaporation and maintain the health and growth of cultured organisms. The average water volume in commercial RAS varies depending on the size and type of fish cultured, the level of production, and the specific design of the system. For example, for 5000 tons of salmon, you need 2.5 m3 millions of new water per year.

What if the RAS discharged water is treated and used as technical water for other industries?

Technical water means water used for technical purposes, such as water used in industrial processes, cooling systems, or manufacturing purposes. This water needs to meet certain standards and specifications depending on the specific application (water quality, temperature, flow rate, etc.).

Aims & outcomes

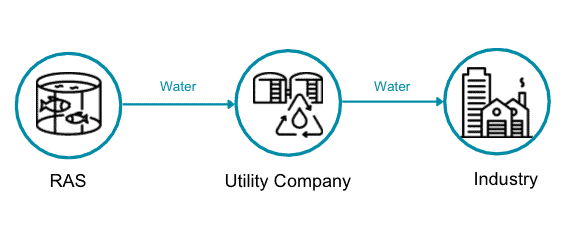

Pilot 1 aims to test the best available technologies to demonstrate that discharged water from a RAS facility can be treated to meet the quality requirements to be used as technical water for other industries. Pilot 1 evolves around the business symbiosis between a salmon RAS, which supplies partially purified water, a municipal utility company that processes the water from RAS to technical water –according to the quality requirements set by the end industry, and the industry as end-users of the water. In the pilot, selected technologies will be tested in a large-scale experiment using RAS water to assess their capacity to meet quality requirements set by the industry.

As part of Pilot 1 activities, a report and a business case for the Best Available Technologies (BAT) for water treatment systems will be developed. The business model will be transferrable to other Baltic Sea regions.

Relevance

Establishing the best available technologies for using treated RAS-discharged water for industrial processes opens an immensity of possible synergies between RAS production and industry, to mention a few: RAS facilities, concrete foundries, power plants, data centres, and all industries requiring water for their processes.

Improving water efficiency use in recirculating systems contributes to sustainable water use and groundwater conservation and enhances the environmental footprint of RAS.

Vision & Impact

Annette Løttrup-Moore, Business Developer at Business Lolland-Falster shared “BLF is hoping that partaking in TETRAS will provide some technical solutions which can pave the way for investment in sustainable aquaculture in Lolland-Falster, Denmark.”

Per Dolmer, from Blue Research shared his vision about the project and Pilot 1: “The production of fish in land-based systems, where the water I reused many times (RAS), reduces the impact on the ecosystem in relation to some parameters as eutrophication, fish escaping the nets, and biosafety, among others. On the other hand, the RAS technology requires a lot of energy for water pumping, water treatment, and building the system. Water is a limited resource, both from a local and global perspective. The future growth and implementation of green solutions, such as P2X, are dependent on clever water solutions. Hence, other industries using large amounts of water for technical processes can benefit from cooperation with the RAS by reusing the water after the final treatment, instead of discharging it to a recipient.”

Contact

Annette Løttrup-Moore

alm@businesslf.dk

Interactive map showing pilot locations. Use the arrow keys to move the map view and the zoom controls to zoom in or out. Press the Tab key to navigate between markers. Press Enter or click a marker to view pilot project details.