Maritime industry in the Baltic Sea region needs innovative ideas to keep up with strict environmental regulations while maintaining competitiveness. Driven by eco-efficiency, the ECOPRODIGI project developed and piloted digital solutions to better measure, visualise and optimise maritime industry processes.

The digital leap and how to take it

Digitalisation journey is often a long one, encompassing technology, people and processes. In most cases, there are various steps that need to be taken to digitalise operations in a comprehensive and beneficial way. Resources in the form of time, money and patience are needed.

In order to consider all the various aspects of digitalisation and to maximise the project’s scope and impact, collaboration between different stakeholders was an essential feature of the ECOPRODIGI project right from the start. The project brought together 21 partner organisations, e.g. research institutions, shipping companies, shipyards, digital solution providers from Denmark, Finland, Lithuania, Norway, and Sweden. Approximately half of the organisations represented maritime enterprises which enabled the project to focus on and respond to the needs of the end-users.

Guided by interest in the complete life-cycle of vessels, the project worked on three concrete industry cases: digital performance monitoring of vessels during voyages at sea, cargo stowage optimisation at ports and streamlining processes at shipyards. All of these cases aimed at making the Baltic Sea region a front-runner in maritime industry digitalisation and clean shipping.

Discovering bottlenecks and ways to overcome them

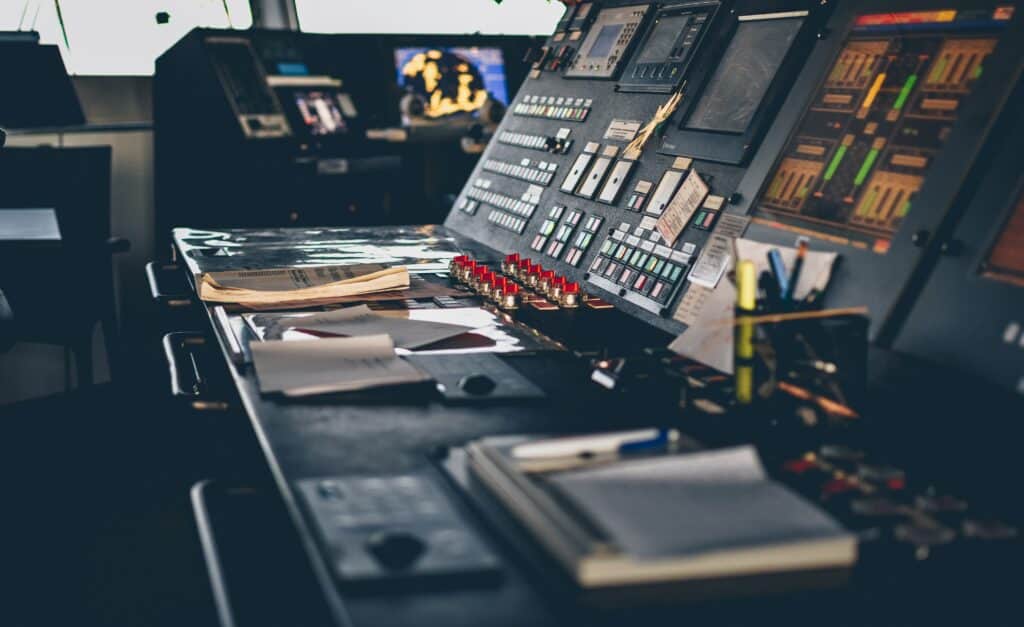

Performance monitoring of vessels is key to assess factors that could affect the fleet’s operational efficiency, such as fuel consumption, equipment availability and equipment deterioration. With the help of digital technologies, it is possible to collect and evaluate real-time operational data from vessels, enabling the personnel to make more informed and efficient decisions. ECOPRODIGI researchers analysed the current state of fleet and vessel operations of three case companies Island Ferry Secretariat, J. Lauritzen and Ardea, In each case, they discovered several eco-inefficiencies that could be improved with the help of new digital technologies. Based on these findings, the partners began to develop new models and digital solutions helping the crew to make optimal decisions and reduce emissions when sailing on the sea. For example, a prototype digital tool was developed to visualise fuel consumption and to provide sailing recommendations for small ferries based on different sailing conditions.

Using advanced digital technologies for the optimisation of cargo stowage processes at ports is beneficial for both the environment and terminal operations. It contributes to lower fuel consumption and emissions, reducing port stays as well as decreasing the overall expenses. ECOPRODIGI partners investigated eco-efficiency bottlenecks in the loading and discharging of vessels at the Danish shipping and logistics company DFDS. The researchers and digital solution providers created and tested several digital tools, together with DFDS to access more accurate data on cargo helping to optimise stowage operations. For example, researchers in Norway created mathematical models and a simulation tool, which helps a shipping company to see the impact of dual-cycling, the simultaneous loading and unloading of containers, making the stowage process faster. Piloting of this digital technology enabled to shorten the port stays of the vessels so that they could leave the port earlier and sail more slowly while still reaching the next port on time. Reducing the speed of vessels decreased fuel consumption and thereby also harmful emissions.

The need to reduce emissions and optimise processes is relevant also for shipyards where vessels are built and repaired. ECOPRODIGI partners studied processes and supply chain management at the Meyer Turku shipyard in Finland. Based on the bottlenecks discovered, the partners developed a production system to improve work planning, warehouse management, reporting of deviations and defects, data tracking and monitoring. This improved the overall efficiency of shipyard production processes from the warehouse to assembly, resulting in savings in materials and working hours.

Furthermore, in Lithuania and in Finland, ECOPRODIGI researchers and shipyard representatives worked with 3D technology to upgrade ships and optimise the manufacturing process of blocks. 3D scanning technology was utilised to improve quality control of products as well as to save material, energy and time spent in rework resulting from deviations.

In addition to the three industry cases, ECOPRODIGI focused on supporting the future actions of maritime organisations in several ways. First of all, the project developed digitalisation roadmaps for upcoming ten years, which maritime organisations can use to set benchmarks. Secondly, the partners created training programmes concerning the use of new digital tools for current and future maritime industry employees. Thirdly, the project brought together the public and private sector in several seminars to discuss how the maritime industry can be supported by moving towards more digital and eco-efficient operations. The seminars produced also concrete policy recommendations for policymakers.

Digital technologies as enablers for better productivity and sustainable operations

Based on the results of the three technology cases, project partners discovered that digital tools and solutions can reduce fuel consumption and emissions from shipping by up to 20%. The use of digital technologies can also significantly help to increase the eco-efficiency of production processes. In addition, the partners’ work on training programmes revealed the great potential of digital tools in maritime industry education and training. ECOPRODIGI also demonstrated the importance of transnational cooperation between research, industry, and policymakers in developing and promoting new technologies and solutions.

“Shipping industry is global and the International Maritime Organization has the main role in creating a regulatory framework for it. To comply with these regulations and achieve other targets towards more sustainable shipping, transnational cooperation between research, industry and policy makers in developing and promoting new technologies and solutions is crucial. Thus, we can innovate solutions the developers are able to produce and that the end-users are able to obtain and use as well. This was clearly demonstrated in ECOPRODIGI”, confirms Senior Researcher Tapio Karvonen from the University of Turku.

© University of Turku. Photograph by Noora Mela

While the project’s findings on the potential of using digital technologies were largely positive, the results also indicated that there is a significant potential for further advancement of digital technology, solutions and applications and that more investments in research and development are needed. Furthermore, to promote a wider-scale use of digital tools and solutions in the maritime industry, standardisation of several procedures and processes is crucial.

How will the achieved results be used in the future?

The extension stage project EXOPRODIGI essentially builds on the lessons learned from ECOPRODIGI. Similar to ECOPRODIGI, the aim in EXOPRODIGI is to enhance the institutional capacity of maritime industry end-users at various stages of vessel life-cycle; i.e. during voyages at sea, stowage operations at ports, and the assembly processes at shipyards. EXOPRODIGI develops further and expands the use of several of the solutions developed in ECOPRODIGI. Moreover, it tests some totally new tools and methods. For example, partners use 3D technology to scan an entire production facility in Klaipeda, Lithuania, creating a digital twin of the facility. The use of digital twin, among others, improves the layout and production planning in a shipyard environment.

Article written by Emilia Tuominen, Centrum Balticum Foundation and Elisa Aro, Pan-European Institute (PEI), University of Turku.