CIRC-2-ZERO Project II Co-Creation Workshop

14 January 2026

CIRC-2-ZERO Project II Co-Creation Workshop on the Development of DTDP Module 1

The CIRC-2-ZERO Project successfully held its second Co-Creation Workshop online (14.11.2025), organised by the project’s lead partner, Häme University of Applied Sciences (HAMK). The workshop represented an important milestone in the development of the Digital Twin Demo Platform (DTDP), specifically addressing the definition of functionalities for DTDP Module 1.

Workshop Objectives

The workshop pursued two primary objectives:

- to identify and select the most relevant environmental and economic indicators for integration into the Digital Twin Demo Platform; and

- to explore and define the relationships between these indicators and the key manufacturing challenges faced by the project’s target industry sectors.

Discussions and analyses were conducted from the perspectives of the project’s two target sectors: Electronics and Engineered Wood Products (EWP).

Advancing the Design of DTDP Module 1

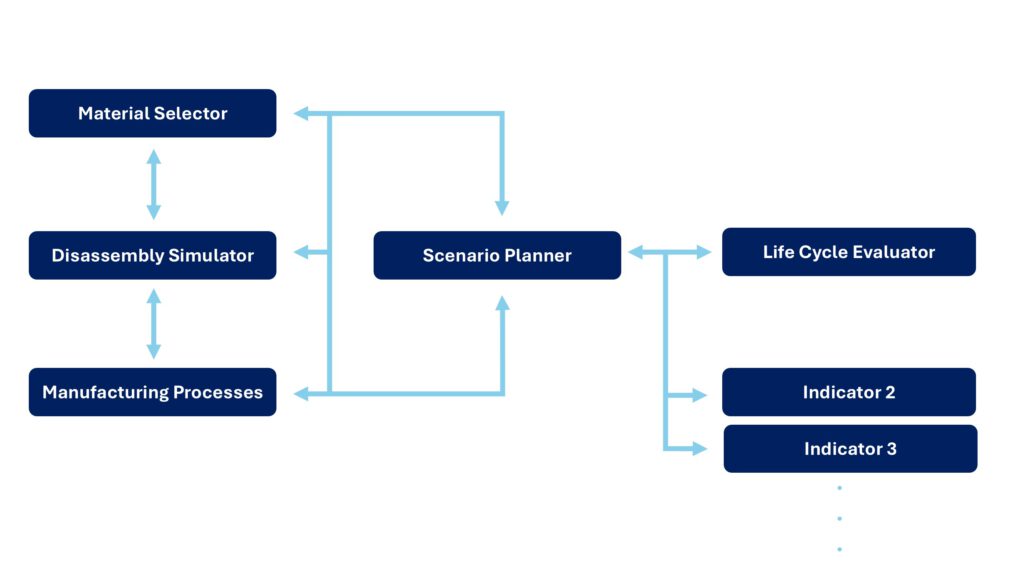

The workshop opened with a presentation of the initial design and functionality logic of DTDP Module 1. Participants were introduced to the platform’s core components, including the Material Selector, Disassembly Simulator, Manufacturing Processes module, Scenario Planner, and Life Cycle Evaluator. Together, these functionalities enable users to select recyclable materials, assess disassembly feasibility, simulate manufacturing processes, and rank alternative scenarios based on environmental and financial performance.

Special emphasis was placed on the Scenario Planner, which was highlighted as the central decision-support function within the platform. Participants engaged in in-depth discussions on how to define and limit the number of indicators included in Module 1, ensuring they are both practical and impactful for users. Key questions addressed included which indicators deliver the greatest value to SMEs, which have the strongest relevance for the Electronics and EWP sectors, and which can help companies anticipate future regulatory requirements.

Environmental and Economic Indicators as Core Building Blocks

Economic indicators were discussed as essential quantitative measures reflecting business performance and operational efficiency, such as production costs, logistics costs, and output per labor hour. Environmental indicators, including emissions, waste management, and resource use, were recognized as critical tools for monitoring sustainability performance and reducing environmental impact.

To support effective decision-making, a pre-list of indicators was prepared in advance of the workshop. This enabled participants to efficiently select indicators most relevant to both target sectors. The selected indicators were aligned with key EU regulatory frameworks, including the Corporate Sustainability Reporting Directive (CSRD) and the Ecodesign for Sustainable Products Regulation (ESPR), as well as leading circular economy methodologies such as the Circular Transition Indicators (CTI) and the Material Circularity Indicator (MCI). This ensured comprehensive lifecycle coverage while addressing sector-specific priorities.

By integrating both economic and environmental indicators, the Digital Twin Demo Platform aims to support SMEs in building more sustainable, resilient, and efficient supply chains. The platform will enable companies to simulate financial and operational scenarios while simultaneously modeling environmental impacts such as greenhouse gas emissions, energy and water consumption, and material recovery rates. This integrated approach allows SMEs to evaluate trade-offs between economic performance and environmental responsibility, supporting informed decisions aligned with circular economy strategies and regulatory compliance.

Supporting SMEs in a Changing Regulatory Landscape

Workshop discussions strongly reflected the increasing pressure on SMEs to respond to tightening environmental regulations. As critical actors within industrial value chains, SMEs must proactively adapt to evolving requirements by implementing compliance strategies, investing in greener technologies, and aligning operations with higher sustainability standards. Failure to do so may threaten both competitiveness and long-term business continuity.

For the EWP sector, the selected environmental indicators included Non-Renewable Material Use, Wood Sourcing from Sustainable Forests, Product Lifetime (Durability), Repairability, and Material Recovery Rate. In the Electronics sector, priority environmental indicators focused on Upgradability, Energy Efficiency, and Cost Savings from Circular Practices. On the economic side, EWP emphasized Material Cost per Unit of Product, while Electronics prioritized both Energy Cost per Unit of Product and Material Cost per Unit of Product.

Identifying and Prioritizing Manufacturing Challenges

The final phase of the workshop focused on narrowing down manufacturing challenges to those that are feasible to address within the scope of the CIRC-2-ZERO Project. Participants mapped the relationships between the selected environmental and economic indicators and key manufacturing-stage challenges in both sectors. This process enabled the group to prioritize the most relevant and impactful issues, ensuring strong alignment with project objectives and the practical needs of industry.