Estonia's path as a pioneer of serial renovation

19 November 2025

It can be found throughout Europe, yet it is mainly associated with Eastern Europe, the Baltic Countries and Central Asia. Prefabricated buildings, typically manufactured in series, are considered a relic of the Soviet era. Considered? Even today, housing is still being manufactured and built in series. It now goes by other names such as prefabricated houses, prefabricated construction, modular or serial construction.

There are indeed many prefabricated buildings in Eastern Europe. They are in poor condition and ownership is not always clear. More than 90% of these houses are organised into homeowners’ associations or are owned by homeowners and not organised. After the collapse of the Soviet Union, the flats were privatised and given away to the residents by governments, cities and municipalities. Those who often live in their own flats frequently lack awareness of their ownership. Repairs are carried out in their own flats, but communal areas are not considered and the need for their own action for repair and renovation work in and around the building is not recognised. The necessary action is not taken.

Homeowners’ associations are more sluggish in their decisions; votes and majority resolutions are required before measures can be carried out on and in the building. In addition to a lack of capacity in the construction industry, this slows down renovations and hinders the path to climate neutrality in the building sector, to which many countries have committed themselves.

The Interreg project RenoWave, with partners from Sweden, Finland, Estonia, Latvia, Lithuania, Poland and Germany, is addressing these two obstacles. As part of the project, guidelines were developed on how municipalities and countries can support their homeowners’ associations in maintenance and energy-efficient renovation measures by creating an institution dedicated to addressing the issue. This institution can act as a one-stop shop that advises owners on energy efficiency in and around buildings but can also provide support in planning and implementing specific measures.

For typical types of buildings such as prefabricated concrete slab buildings, the project partner Housing Initiative for Eastern Europe (IWO) drew attention to a new renovation approach, serial renovation. It works on the principle that “what was built in series can also be renovated in series”. This approach is generally suitable for almost all buildings but is best suited to buildings constructed in series or standardised buildings.

As part of the RenoWave and FELICITY II projects, a study trip to Estonia organised by IWO took place in October 2025 on the topic of serial renovation and construction and, associated with this, project management for renovation projects in multi-family houses.

Innovation, practice and perspectives in building renovation

Estonia is a pioneer in serial renovation. In this Baltic country, 50 houses have been renovated according to this principle to date. Nowhere else in Europe are there more completed serial renovation projects, and nowhere else is there more experience with this forward-looking approach.

Ukrainian, Swedish, Lithuanian and German representatives from local authorities and NGOs gained in-depth knowledge of serial renovation in Estonia. They saw and visited serially renovated apartment buildings in Tallinn and Tartu, examined this special renovation approach and the Estonian subsidy conditions for renovations in detail, and visited the factory of the manufacturer Matek AS, where panel elements for serial renovation are produced.

Reaching the goal faster

Serial renovation is a very good way of achieving the ambitious European climate protection targets for the building sector on time, according to Martin Kikas, head of the Tartu TREA energy agency. Advantages include scalability through industrial prefabrication of the elements, especially for houses of the same type, short construction times, reduced need for skilled workers and the possibility for residents to remain in their homes with relatively few limitations during the renovation.

Serial renovation is an energy-efficient renovation using prefabricated façade and roof elements. The outer shell of the building is measured precisely using a 3D laser scan. This forms the basis for the planning and then the manufacture of the elements. They are manufactured in a factory, transported to the construction site and attached to the outer shell of the building there with the help of a crane and two workers. These elements fulfil the functions of insulating the outer shell and replacing the windows in one go. In addition, other building services can be housed and thus renewed in them, such as ventilation pipes for a ventilation system or heating and water pipes. Solar panels can be installed on roof and wall elements, and balconies and lifts can also be attached to the panels.

The suitability of the outer shell is confirmed in advance by test drilling and material analysis. The elements can only be securely attached if the concrete is still strong enough and not porous. They are attached to the outer shell with strong anchors and connected to each other. The system follows a modular principle, as if a second shell were being built around the house. The elements are made of wood, making them lighter, sustainable and recyclable. The size of the elements is adapted to the building, but is approximately 9 m x 2.5-3 m. The thickness of the element depends on how much insulation the building needs and whether other systems such as pipes are included. The automation of the manufacturing process saves time, and the construction time is also extremely shortened compared to conventional renovation methods. An element can be installed in 15-20 minutes, so that the time required for the entire installation of the elements for an apartment building with, for example, 80 residential units and 3500m² of living space can ideally be as little as 6-8 weeks.

Opportunity recognised, political direction adjusted

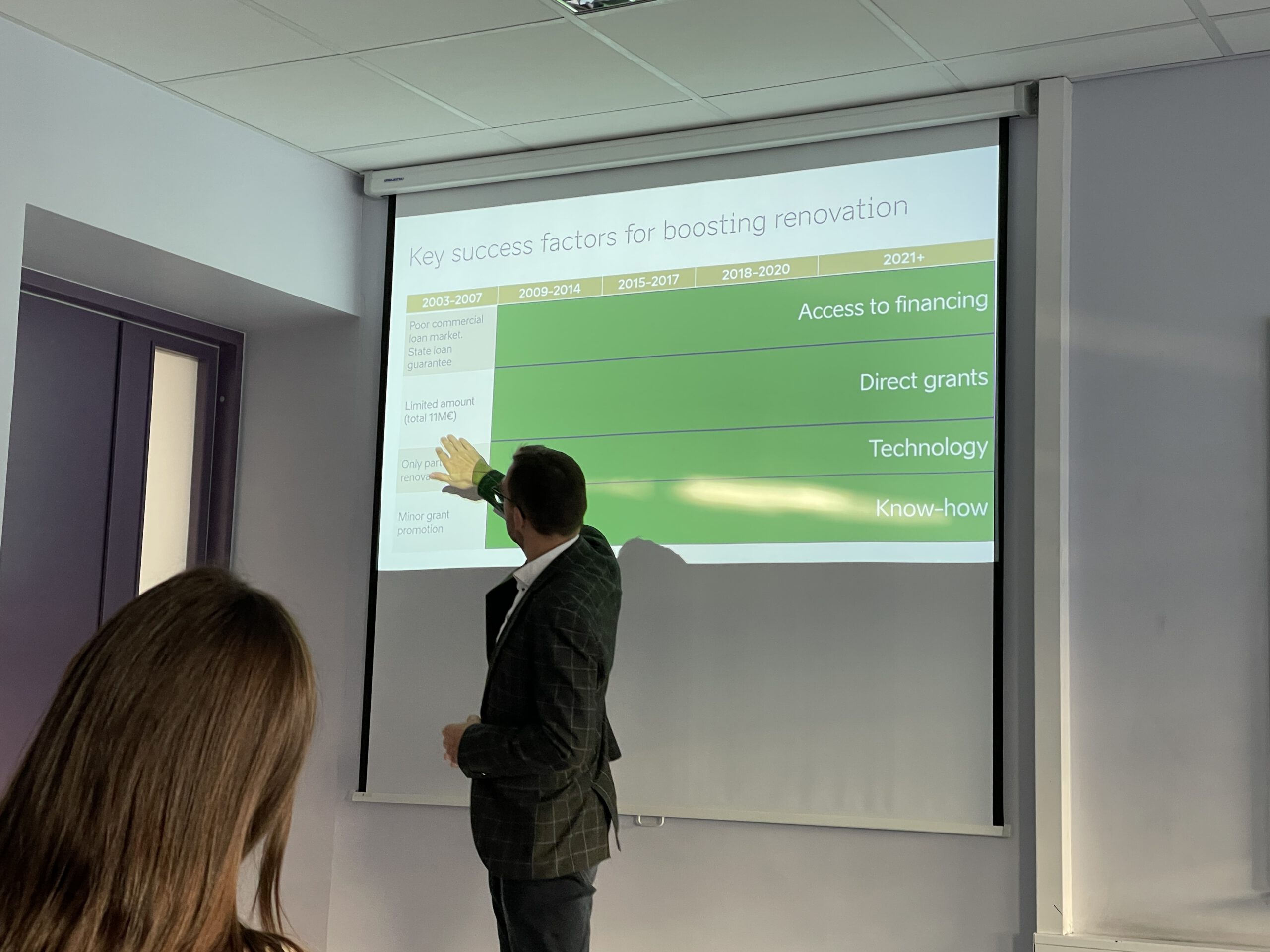

As Ivo Jaanisoo from the Estonian Ministry of Climate explains, the Estonian government quickly recognised the potential and adjusted the subsidy systems and funds for renovations. While only €11 million in subsidies were granted for individual renovation measures between 2003 and 2007, since 2021 more than €350 million has been made available for complete renovations and serial renovations. The credit system has stabilised and the state guarantees for bank defaults on renovation loans.

For Annely Känd of Woodhouse Estonia, it is clear why these industrial structures for serial renovation have developed in Estonia in particular. On the one hand, there was already large-scale production of panels for serially built apartment buildings during the Soviet era, so the conversion of this industry is logical, as it is well known and in the public consciousness. On the other hand, wood is a resource that is well available and stable in Estonia. The further development of this special industrial approach with a large digital component also speaks to the heart and self-image of Estonians, who are known to be digital pioneers in Europe.

Neighbourhood as a driver of renovation

According to Anu Sarnet from the Estonian Association of Condominium Owners (EKÜL), particular attention must be paid to social factors when it comes to complex methods such as serial renovation. In Estonia, apartment buildings are largely organised into homeowners’ associations. In these associations, measures relating to the building must always be decided by a majority of the owners. Successful communication is essential in this regard. A balance between good technical explanations and sensitivity and understanding for the personal situation of the individual owners is essential in order to bring about a decision for a deep renovation.

A socially innovative, integrated approach can be found in Tallinn: the SOFTacademy project, which focuses on neighbourhood-based renovation. The aim is to renovate several buildings of the same type together and at the same time upgrade the courtyards between the buildings. The city takes care of the courtyard design when the buildings undergo deep renovation. This is an incentive for collective action. At the same time, the joint renovation of four neighbouring buildings is intended to save costs, and serial renovations are intended to shorten the planning and renovation process itself.

The project integrates creative participation formats such as workshops, hackathons, painting competitions and focus groups with residents of the buildings. Not only technical aspects are discussed, but also social and design issues, such as colour schemes, the integration of art and the use of parking spaces. The challenges are manifold, says Kadri Auväärt, project manager of the SOFTacademy project, ranging from legal issues and social tensions to a lack of trust in urban processes.

Aiming high

In Tartu, Annika Urbas, project manager at TREA, shows us a test building in a prefabricated housing estate on the outskirts of the city. There are 22 similar buildings there, each with more than five floors. These are also to be renovated soon and quickly. The serial approach for these similar buildings would be appropriate and is desired. In the Tartu Energy Agency’s oPEN Lab research project, tests are now being carried out on a five-storey building in the same neighbourhood, originally constructed with the same panels, to see whether other anchoring options for the panels in the original building wall would allow buildings taller than five storeys to be renovated in this way. Due to the statics and weight of the elements, it has not yet been technically possible to renovate buildings taller than five storeys with prefabricated elements. That is set to change soon.

Matek AS, Estonia’s oldest manufacturer of wooden panels, based in Pärnu, has also been making great strides in Europe for several years. Kaarel Väer, sales manager at Matek, speaks enthusiastically about the positive development of his company. References in Estonia, Finland, Sweden, Norway, Denmark, Lithuania and now Germany pave the way for the company’s success. They not only renovate in series, they also build in series. They build modularly. The modules can measure a maximum of 4.2 m wide, 12 m long and 3 m high, otherwise they cannot be transported. In the factory hall, everything appears very simple and clear, just like the idea itself. It is tidy, workers are screwing and measuring, each at their own panel, every hand knows what to do. The panels for the renovations are lined up in rows next to each other. In another hall, several building modules stand next to each other. Like Lego bricks, they will later be stacked on top of and next to each other by a crane on the construction site, then connected to each other, and in no time at all they will have become a large house.

Solution for Estonia, opportunity for Europe

The speed of the serial renovation and construction approach is a great opportunity for Europe. Building stock in member states could be renovated more quickly, more efficiently and also more cost-effectively if the approach were to go into mass production. This would be an effective and quick way to solve the housing shortage. The shortage of skilled workers in the construction industry could be circumvented, as the prefabrication of elements and modules would mean that fewer trades would be employed on construction sites. Construction times would be shortened, and on-site construction work would be less dependent on the weather and could be carried out in both summer and winter.

For Ukraine, the serial approach could be the key to successful reconstruction. Serial wall elements are not only suitable for renovating ageing Soviet buildings that have already exceeded their duration of life, but also for repairing damaged buildings. With timber modular construction, new residential buildings can be erected quickly and without much effort.

In cooperation with Matek AS, an initial pilot project is underway in Nizhyn in the Chernihiv Oblast in northern Ukraine. It will show whether the approach can be established in Ukraine. According to Knut Höller, Managing Director of IWO e.V., stable funding opportunities, international investment and changes in policy are important for this, in addition to an initial successful pilot project.

The RenoWave project partners, especially IWO (Germany) and Dalarna County (Sweden), will continue to support the Ukrainian building sector even after the project ends in December 2025. Serial renovation and good project management for renovation projects can be an important lever in rebuilding the country for more and better housing. The aim of the study trip to Estonia in October for project partners from Ukraine and the Baltic Sea region was to see good practice examples in order to demonstrate these experiences and opening opportunities going other ways. Many thanks to the funding bodies Interreg Baltic Sea Region and the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH for making the trip possible.

—

The project “One-Stop-Shop extended model to increase the multi-apartment building stock renovation in the BSR” (RenoWave) is implemented with the support of the EU funding programme Interreg Baltic Sea Region 2021-2027. The project develops a One-Stop-Shop extended model specifically designed for multi-apartment buildings in Baltic Sea Region countries. Partner countries are Sweden, Finland, Poland, Germany, Lithuania, Latvia and Estonia.

The FELICITY II project is implemented by Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH in cooperation with the European Investment Bank and with the support of the German Government, under the framework of the International Climate Initiative (IKI).