One Truckload at a Time Towards a Circular Economy

08 May 2025

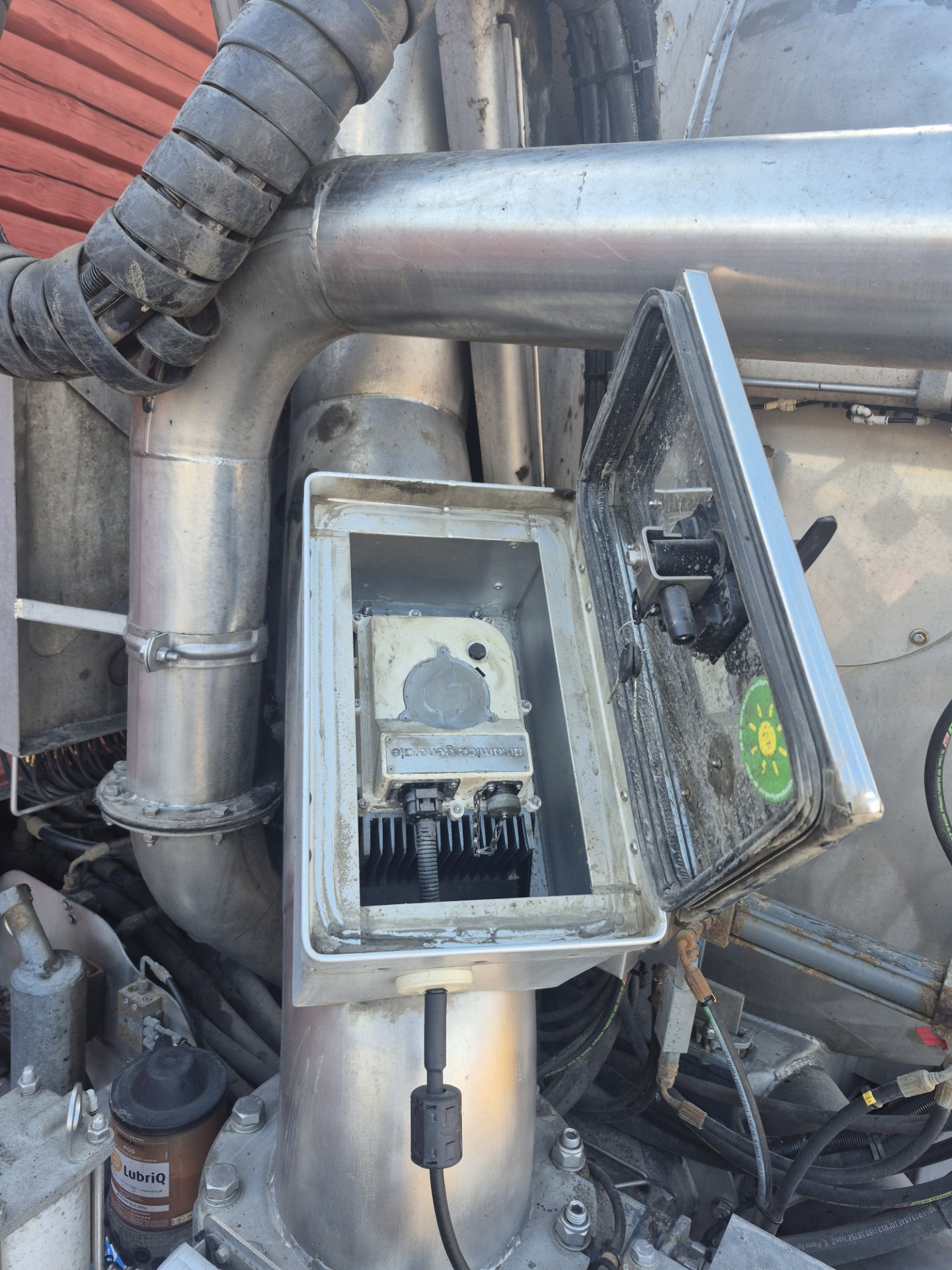

NIR stands for Near-Infrared Spectroscopy, which, in simple terms, measures light. When used on materials such as sludge, slurry, or digestate, the different components in the biomatter reflect light in unique ways. By measuring the reflected light, it is possible to draw conclusions about the material’s content. This data can answer a number of technical questions like “Does it contain phosphorus?” or “What is the total solids content?”. Tero’s NIR meter is mounted on his truck and takes real-time measurements during loading. A sample is taken every second during the loading process. Each loading takes approximately four minutes and loads about 40 m³ of biomaterial. During this time, 240 individual measurements are taken and used to form an average analysis per load.

The device analyzes the following key nutrients and properties:

- Moisture

- Total Nitrogen (N)

- Ammonium (NH₄)

- Potassium Oxide (K₂O)

- Phosphorus Pentoxide (P₂O₅)

It is precisely this high-frequency and real-time data that is valuable to both science and clients.

The value lies in providing essential information early in the nutrient recycling process. Currently, farmers and biogas plants are the main clients and key players in nutrient recycling, as they both use slurry, sludge, and digestate in their operations. Farmers use these materials as fertilizers, while biogas plants use sludge and slurry as raw materials for energy production. However, neither farmers nor biogas plants typically conduct frequent analyses of incoming or outgoing materials. Biogas plants, for example, usually test their end product—the digestate—only four times per year, while Tero can obtain similar data during each loading.

Tero’s new equipment can determine the exact composition of the biomatter in real time. This means that farmers receiving, for example, digestate from biogas plants now get up-to-date data on the composition of the load they are receiving. For farmers, variation in the composition of sludge, slurry, and digestate is important. The quality of the digestate may vary from week to week, and such fluctuations often go undetected in quarterly reports. The variation in the digestate is a result from using different feedstocks at the biogas plant, as these plants can use a great many feedstocks for their operations. Receiving composition data upon delivery helps farmers avoid over- or under-fertilizing their fields, ultimately saving costs and improving efficiency.

This is the idea behind the CiNURGi pilot activity in which Tero is participating. NIR technology is still a relatively new approach in nutrient recycling, and Tero’s company is at the forefront of this pilot. The specific NIR meter used is an Italian product certified by the DLG (German Agricultural Society), which means it has received official certification for fertilizer analysis in Germany.

As part of his collaboration with CiNURGi, Tero sends the NIR readings from his deliveries to Biopaja, an experimental facility that is part of LUKE—the Natural Resources Institute of Finland. Biopaja focuses on recycling nutrients from various biomasses, using technologies such as biogas production, pyrolysis, and nutrient recovery to process materials into energy, fertilizers, and other products. At Biopaja, laboratory analyses are performed on samples from Tero’s truck and compared with the NIR readings to validate their accuracy.

Biopaja is one of CiNURGi’s Support Centers that produces recycled nutrient fertilizers as part of the project’s effort to pilot and evaluate innovative solutions. As CiNURGi aims to promote the acceptance and use of recycled nutrients, these Support Centers play a key role in enabling knowledge-based decision-making and improving nutrient recycling. Other Support Centers are located in Sweden and Poland.

When asked about his investment in NIR, Tero shares how he came across the technology:

“It all started with VM Tarm,” says Tero, referring to the semitrailers brand he is a service partner to in Finland.

“I saw a picture of the first-ever NIR meter installed on a VM semitrailer in Denmark and realized the technology had limitless potential. My thought process began with recognizing that if I could measure the total solids in any delivered load, I could help biogas plants optimize their operations. Another major benefit would be managing local phosphorus levels in agriculture, which is especially important since we operate in an area with historically high levels of phosphorus in the soil — in a catchment area of the Baltic Sea. This also represents a sustainable business model where we promote environmental responsibility while offering valuable information to our clients. Our clients like to know what they’re getting.”

Tero has already noticed rising interest in NIR technology while exploring future business opportunities. If collaboration between farmers and biogas plants grows, the plants could benefit from knowing the total solids and phosphorus content in each delivered load. Meanwhile, farmers would be better equipped to make informed decisions about fertilizer use, potentially reducing their reliance on mineral fertilizers. This would contribute to the goal of reducing eutrophication in the Baltic Sea, as outlined in the European Union’s Baltic Sea Region Strategy.